1-April-2019: The global 3D printing metals market size is expected to reach USD 3.05 billion by 2025, according to a new report by Grand View Research, Inc., progressing at a CAGR of 31.8% during the forecast period. Increasing adoption of 3D printing as a mainstream manufacturing method and rising investments in research & development (R&D) of 3D metal printing are anticipated to fuel product demand. Use of 3D metal printing is prominent in the aerospace & defense industry owing to rapid prototyping and manufacturing speed offered by 3D printing.

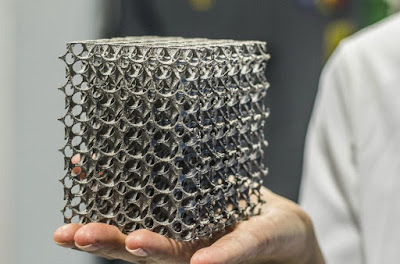

The aerospace & defense (A&D) industry was an early adopter of the product. This is leading to high utilization of materials such as titanium and steel in this industry. 3D printing grants flexibility to produce complex equipment geometries, which are otherwise difficult to build using a traditional manufacturing.

The powder segment dominated the market in 2017. It is expected to progress at a higher CAGR in terms of volume over the forecast period. High packing density and spherical morphology of metal powders ensure good flowability that leads to consistent and predictable powder dosing and layers.

Titanium was the largest contributor to market growth in 2017, owing to its significant adoption in aerospace applications. Titanium-based alloys have a very high melting point and are strongly resistant to oxidation and acids. This is necessary for manufacturing critical aircraft parts. Moreover, aircraft designers are able to achieve higher thrust to weight of engine ratio due to high strength and low density of titanium.

North America emerged as the largest region in 2017 in terms of employing 3D printing metals. Presence of numerous aerospace companies are expected to stoke the growth of the regional market. Moreover, high defense expenditure across the region is anticipated to boost the utilization of the product in aerospace & defense.

The U.S. has been a major producer and consumer of 3D printing metals on a global scale. Presence of key industry players such as 3D Systems Corporation and ExOne GmbH is expected to drive the market on account of innovative product launches and expansion initiatives in the country. Moreover, increasing integration of advanced technologies such as 3D printing with several manufacturing processes has been escalating the growth of the market in the country.

Technological limitations of additive manufacturing for large-scale production of heavy parts are the primary factors restraining market growth. In addition, high-cost of printers and raw materials such as metal powders is also anticipated to negatively influence the growth of the market.

However, rising investments in R&D activities by academicians and companies are expected to facilitate cost reduction as well as increased utilization of the product. Major players in the global industry are involved in launching new products, joint ventures, and acquisitions to increase their customer reach in the international markets.

In depth research report on 3D Printing Metal Market

Further key findings from the report suggest:

· Aerospace & defense is anticipated to witness the fastest growth at a CAGR of 34.2% over the forecast period, in terms of revenue, on account of reduced lead time offered by 3D printing and increasing demand for highly customizable parts

· The titanium segment captured the highest revenue share of 63.0% in 2017 due to its high corrosion resistance, high tensile strength, and low density

· The 3D printing metals market in Asia Pacific was valued at USD 79.7 million in 2017 with China and Japan emerging as major markets.

· In terms of volume, the powder segment accounted for 92.6% of the market in 2017 owing to superior quality offered by metal powders for manufacturing process of metal parts

· Key companies are attempting to provide superior quality products and expand their product portfolio. For instance, in September 2017, ExOne expanded its product offerings by announcing availability of 17-4PH stainless steel as a printable material.

Grand View Research has segmented the global 3D printing metals market on the basis of form, application, product, and region:

3D Printing Metals Form Outlook (Revenue, USD Million; Volume, Tons, 2014 - 2025)

· Powder

· Filament

3D Printing Metals Application Outlook (Revenue, USD Million; Volume, Tons, 2014 - 2025)

· Aerospace & defense

· Automotive

· Medical & dental

· Others

3D Printing Metals Product Outlook (Revenue, USD Million; Volume, Tons, 2014 - 2025)

· Titanium

· Nickel

· Steel

· Aluminum

· Others

Browse more research reports of this category:

About Grand View Research

Grand View Research, Inc. is a U.S. based market research and consulting company, registered in the State of California and headquartered in San Francisco. The company provides syndicated research reports, customized research reports, and consulting services. To help clients make informed business decisions, the company offers market intelligence studies ensuring relevant and fact-based research across a range of industries including technology, chemicals, materials, healthcare and energy.

No comments:

Post a Comment